Level Measurement

Level Measurement Specification

- Operating Temperature

- -25C to +70C

- Sensitivity

- Factory Pre-set/Adjustable

- Cable Length

- 2 m

- Measurement Range

- Up to 2 m

- Wireless

- No

- Power Consumption

- <2 W

- Application

- Water, Oil, Chemical Tanks

- Signal Type

- Discrete (Switching)

- Features

- Shock & Vibration Resistant, Maintenance-Free

- Interface

- M12 Connector

- Sensor Type

- Capacitive/Conductive

- Response Time

- <1 s

- Mounting Type

- Threaded (G1/2)

- IP Rating

- IP67

- Product Type

- Baumer Level Switch

- Material

- Stainless Steel (SS)

- Input

- 24 V DC

- Output

- PNP/NPN, 1x Switching Output

- Function

- Level Detection and Measurement

- Usage

- Industrial Liquid Level Monitoring

- Accuracy

- 2 mm

- Resolution

- 1 mm

- Voltage

- 24 V DC

- Weight

- Approx. 350 g

- Ambient Humidity

- <95% RH, Non-condensing

- Approvals/Certifications

- CE, RoHS Compliant

- Protection Class

- Class III

- Enclosure Material

- Polycarbonate

- Operating Pressure

- Max. 10 bar

About Level Measurement

Hygienic design

Hygienic connections conform to 3-A standards, FDA demands and EHEDG guidelines

Precise switching point without calibration

Process temperature

-40...200 °C

Exceptional Durability for Industrial Environments

Manufactured using stainless steel and a polycarbonate enclosure, this level sensor withstands harsh industrial conditions, including shock, vibration, and exposure to chemicals. With an IP67 rating, it ensures dust and water protection, making it a maintenance-free solution for various industries in India.

Precise Liquid Level Monitoring

Offering 2 mm accuracy and 1 mm resolution, the sensor delivers consistent performance in water, oil, and chemical tanks. The factory pre-set or adjustable sensitivity enables customizable operation to suit specific requirements, guaranteeing reliable and swift (<1 s) detection of changes in liquid levels up to 2 meters.

FAQs of Level Measurement:

Q: How is the level measurement sensor installed in industrial tanks?

A: The sensor features a threaded (G1/2) mounting type, allowing for straightforward installation on tank wall or vessel openings. The included 2-meter cable and M12 connector simplify electrical integration without specialized tools.Q: What types of liquids can this sensor be used to monitor?

A: This device is suitable for monitoring water, oil, and a variety of chemicals in industrial tanks. Its durable materials and resistance to shock and vibration ensure reliable operation even in challenging environments.Q: When should the sensor be selected for an application?

A: Choose this sensor when precise level detection (2 mm accuracy) is required for industrial liquid tanks under conditions of high humidity (up to 95% RH, non-condensing), pressures up to 10 bar, and temperature ranges from -25C to +70C.Q: Where has the sensor been approved and certified for use?

A: The sensor is both CE and RoHS compliant, ensuring it meets global standards for safety, performance, and environmental responsibility, which is essential for Indian dealers, importers, exporters, and distributors.Q: What is the process of integrating the sensor into a control system?

A: Integration involves connecting the sensor via its discrete PNP/NPN output to industrial controllers or automation systems. The M12 connector and switching output facilitate efficient signal transmission for liquid level management.Q: How does the sensor benefit maintenance and operational efficiency?

A: The sensors maintenance-free design and robust construction minimize downtime and service requirements. Its fast response time and accuracy enhance process automation, leading to improved safety and resource management.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Process Instrumentation Category

Digital Pressure Sensor

Price 2500.0 INR / Number

Minimum Order Quantity : 1 Number

Product Type : Pressure Sensor

Output : PNP/NPN

Function : Dual Display Digital Pressure Sensor [For Gas]

Sensor Type : Standard pressure port type

Digital Displacement Sensor (Panasonic)

Price 35000.0 INR / Number

Minimum Order Quantity : 1 Number

Product Type : Displacement Sensor

Output : NPN/PNP

Sensor Type : Displacement Sensor

Temperature Measurement

Product Type : Temperature transmitter

Output : Analog signal

Function : Temperature sensing

Sensor Type : RTD / Thermocouple

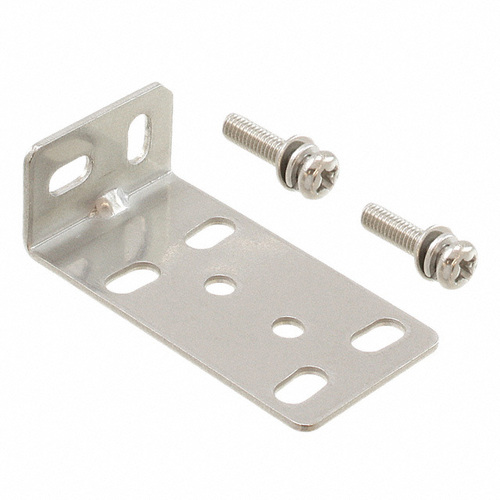

MS-CX2-4 Mounting Brackets

Price 350.0 INR / Number

Minimum Order Quantity : 1 Number

Product Type : MSCX24

Function : Mounting Bracket

Sensor Type : Mounting bracket

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free