Digital Pressure Sensor

Price 2500.0 INR/ Number

MOQ : 1 Number

Digital Pressure Sensor Specification

- Sensor Type

- Standard pressure port type

- Operating Temperature

- +20 Celsius (oC)

- Features

- Dual Display Digital Pressure Sensor [For Gas]

- IP Rating

- IP40 (IEC)

- Response Time

- 3.5 Seconds

- Product Type

- Pressure Sensor

- Output

- PNP/NPN

- Function

- Dual Display Digital Pressure Sensor [For Gas]

- Voltage

- 12 to 24 Volt (v)

- Weight

- 130 Grams (g)

- Usage & Applications

- Gauge pressure

- Rated Voltage

- 12 to 24 Volt (V)

- Warranty

- 1 Year

- Display Type

- Dual Display

- Rated Current

- 20 Milliampere (mA)

- Conductor

- CONNECTOR

- Material

- Enclosure : PBT (glass fiber reinforced), LCD display : Acrylic, Pressure port : Stainless steel (SUS303), Mounting threaded part : Brass (nickel plated), Switch part : Silicone rubber

Digital Pressure Sensor Trade Information

- Minimum Order Quantity

- 1 Number

- Payment Terms

- Cash in Advance (CID)

- Main Domestic Market

- All India

About Digital Pressure Sensor

| Brand | Panasonic |

| Pressure Ranges | -1 to 10bar or -1 1 Bar |

| Model Number | DP-102-E-P DP-101-E-P DP-102A DP101A |

| Output | Analog Voltage 15V / Current 420mA |

| Temperature | -10 to +50 DegC |

| Supply Voltage | 12 to 24 VDC |

| Size | 30x30x42.5mm |

| Protection Type | IP40 |

| Rated current Consumption | 35 mA or less |

| Analogue Output | 0.6 5.0 VDC or 4 20mA |

| Transistor Output | NPN or PNP |

| Response time | 2.5 - 5,000ms (Selectable by key operation) |

| Hysteresis | Minimum 1 digit |

| Pressure Resistance (bar) | 15 Bar |

Model Available:-

- DP-101-E-P

- DP-102-E-P

- DP-101A

- DP-102A

Robust Construction for Reliability

This pressure sensor is engineered with PBT glass fiber reinforced enclosure and stainless steel pressure ports to withstand challenging operating conditions. The mounting threaded part is nickel-plated brass, and the switch utilizes silicone rubber, guaranteeing durability and longevity even in rigorous industrial environments.

Dual Display for Enhanced Readability

Featuring a dual LCD display made of acrylic, the sensor allows operators to view pressure values and settings simultaneously. This makes monitoring gas pressure in real-time efficient and supports quicker decision-making during industrial processes.

Versatile Applications and Easy Integration

Supporting both PNP and NPN output configurations and accepting 12 to 24V power, the sensor can be effortlessly integrated into existing control systems. Its compact build and 130g weight make it suitable for installations by manufacturers, exporters, suppliers, and other stakeholders requiring reliable gauge pressure measurement for gas.

FAQ's of Digital Pressure Sensor:

Q: How do I install the Dual Display Digital Pressure Sensor for gas applications?

A: Installation involves securing the nickel-plated brass threaded mounting part to your system's designated port. Ensure the voltage supply is within the 12 to 24V range and connect the sensor via the provided connector to your control circuit. Detailed instructions are included in the user manual for reference.Q: What materials are used in constructing the sensor and why are they beneficial?

A: The enclosure is made of PBT reinforced with glass fiber for durability, the LCD display is acrylic for clear visibility, the pressure port uses corrosion-resistant stainless steel (SUS303), and the mounting thread is nickel-plated brass for robust attachment. Silicone rubber is used for the switch, contributing to longevity and consistent performance.Q: When should I use the Dual Display Digital Pressure Sensor in my process?

A: This sensor is best used whenever accurate, visible gauge pressure measurement of gas is required-particularly in industrial automation and monitoring applications due to its rapid 3.5-second response time and dual display functionality.Q: Where can this pressure sensor be effectively deployed?

A: The sensor can be installed in factories, laboratories, and facilities where gas pressure measurement is critical and where IP40-rated devices are appropriate. It suits OEM manufacturing, export, wholesale, and retail environments requiring reliable digital pressure sensing.Q: What is the process for reading output data from the sensor?

A: The sensor supports both PNP and NPN output types, and information is displayed simultaneously on the dual LCD screens. Output signals can be integrated with your control devices using the connector interface for real-time monitoring and control.Q: What are the main benefits of using this digital pressure sensor?

A: Key benefits include durable materials ensuring long service life, fast response time for immediate feedback, compatibility with standard industry voltages, simple integration with control systems, and enhanced visibility via dual display, all backed by a one-year warranty.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Process Instrumentation Category

Level Measurement

Product Type : Baumer Level Switch

Output : PNP/NPN, 1x Switching Output

Sensor Type : Capacitive/Conductive

Function : Level Detection and Measurement

Digital Displacement Sensor (Panasonic)

Price 35000.0 INR / Number

Minimum Order Quantity : 1 Number

Product Type : Displacement Sensor

Output : NPN/PNP

Sensor Type : Displacement Sensor

Temperature Measurement

Product Type : Temperature transmitter

Output : Analog signal

Sensor Type : RTD / Thermocouple

Function : Temperature sensing

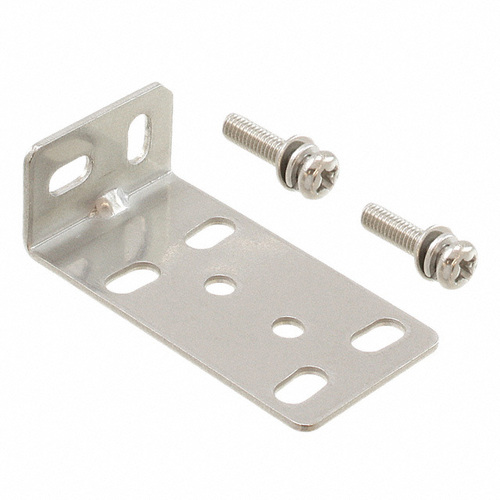

MS-CX2-4 Mounting Brackets

Price 350.0 INR / Number

Minimum Order Quantity : 1 Number

Product Type : MSCX24

Sensor Type : Mounting bracket

Function : Mounting Bracket

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free